Coating Services

PUT A COAT ON, IT´S COLD OUTSIDE!

All the Aluminium AGD supply are made to order. AGD powder coat materials to order and is a great way to distinguish your roofline from project to project.

THE CAST-A-LIKE FINISH

‘Cast-a-like’ is a bespoke Powder Coating finish that is available on all our rainwater goods. It is intended, as the name suggests, to give aluminium the appearance and feel of cast iron. The disadvantages of cast iron are its weight and its susceptibility to rust. Until recently, its dimpled appearance was unique.

However, the cast-a-like finish that is now available combines the appearance of a cast product with the durability of aluminium. The result is a product that has a traditional look and feel, is easy to fit and has a long life span.

The Cast-a-like finish is widely considered as not only an acceptable alternative but also a superior replacement to cast iron. However, many projects on listed buildings are restricted to the use of traditional products.

In addition to the range of extruded aluminium guttering available we can also supply a range of cast aluminium gutters if this is specified. Please contact our Sales Team for more information.

The cast-a-like finish is available on all products and in all colours.

Powder Coating Process

There are three key phases to the powder coating process:

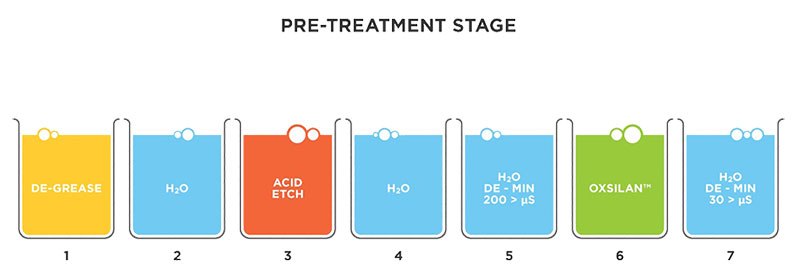

PHASE ONE: Pre-treatment

This stage is vital in allowing the paint finish to perform to its full potential. All paints are porous and will over time allow atmospheric conditions to permeate through the coating onto the metal. To safeguard against this, all substrates are chemically pre-treated in order to protect against corrosion and promote good adhesion.

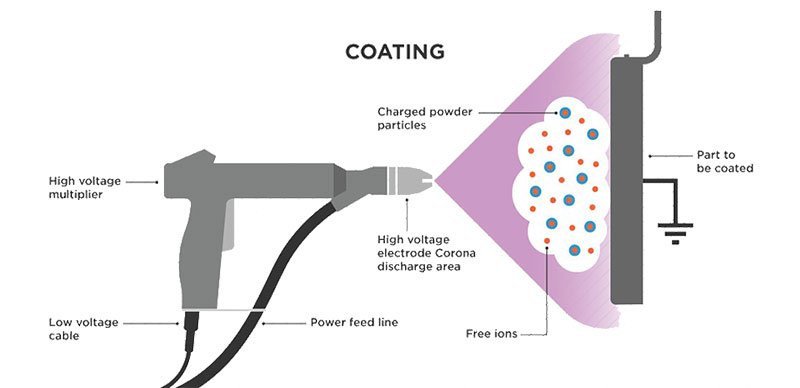

PHASE TWO: Coating

After pre-treatment the metal is suspended on a conveyorised production line and passes into the spray booth for coating. The powder which is held in a fluidised hopper bed is carried to the spray gun using compressed air. As the powder passes out of the gun, the particles are charged and therefore attracted to the earthed piece of metal. This creates an even coating as it wraps around the work piece.

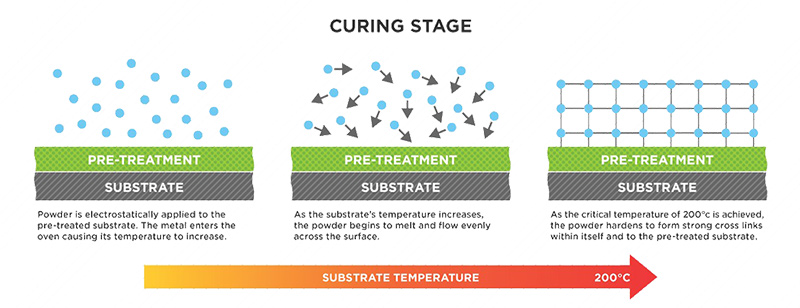

PHASE THREE: Curing

After coating, the production line moves the work into the tunnel oven where it is baked. Once the curing is complete the substrate is inspected for defects, paint thickness, colour and gloss level. Provided there are no issues, the product is packed and made ready for despatch.